EC-JET| Make food traceability more convenient under anti-epidemic

The recent epidemic prevention and control in Beijing has begun to show signs of rebound, and many new local cases are highly related to the new agricultural products wholesale market. According to "Beijing Daily", the new market has detected new coronavirus from the cutting board of imported salmon. The daily food of salmon instantly became a hot topic on the Internet.

In today's severe global epidemic situation, prevention and control are the key to the nation's anti-epidemic, and traceability and traceability are also key to food safety. When consumers choose to buy and eat daily food, they should choose foods that can be traced throughout the entire industrial chain and throughout the process.

Image source: Baidu

Image source: Baidu

As a coded porter, the inkjet printer can realize the function of tracing food product information throughout. Food production enterprises can use the EC-JET printer to print product information on the inner and outer packaging of the product to form a unique identity mark for the product, which is convenient for product traceability. Consumers can trace back to the product as long as they move their fingers Specific production information, logistics and transportation, enterprise information and inspection information.

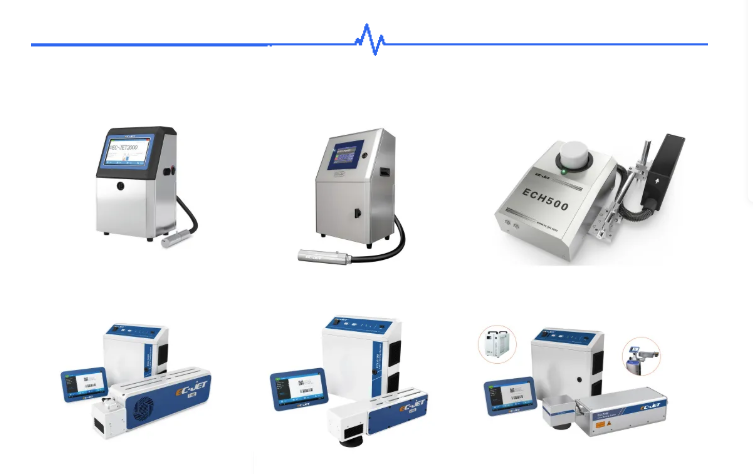

Equipment recommendation

EC-JET2000 is a small-character printer equipment with stable performance, which can complete the marking work in different environments. The printing parameters and font size can be adjusted through the large color screen to meet the needs of rapid printing of product information on different products to form traceability. It can also generate unique logos through graphics, numbers, and letters.

EC-JET2000 is a small-character printer equipment with stable performance, which can complete the marking work in different environments. The printing parameters and font size can be adjusted through the large color screen to meet the needs of rapid printing of product information on different products to form traceability. It can also generate unique logos through graphics, numbers, and letters.

It can realize the remote operation of the local area network, real-time interconnection with the management system of the enterprise, encode and manage the products and components during the printing process, send the corresponding content to the printer, and automatically generate a QR code to dynamically print the product. Avoid errors and increase production efficiency.

Performance characteristics:

1. It can accurately position the printing position on the Tetra Pak carton, PET plastic bottle, glass bottle, composite film, tinplate and other materials to reduce manual errors and make the printing content more neat and beautiful.

2. The electrical appliances and the ink system are isolated from each other, which effectively prevents the oil and dust in the air from entering the circuit board, making maintenance more convenient and safe, and at the same time extending the service life of the machine.

3. New operation interface, color screen device status color auxiliary prompt to improve user experience, real-time monitoring of consumables remaining and accurate percentage prompt, is the best choice for customers.

Case Studies

Consultation hotline: 400-9020866

Consultation hotline: 400-9020866

|

|