The advantage analysis of EC-JET small character CIJ printer

Together with the rapid development of science, technology and economy, inkjet technology has got rapid development, and the market demand for inkjet printers is increasing a lot. In this paper, the basic principle and technical difficulties of small character inkjet are illuminated, and the related technologies and unique advantages of EC-JET small printer character inkjet printer are given as well.

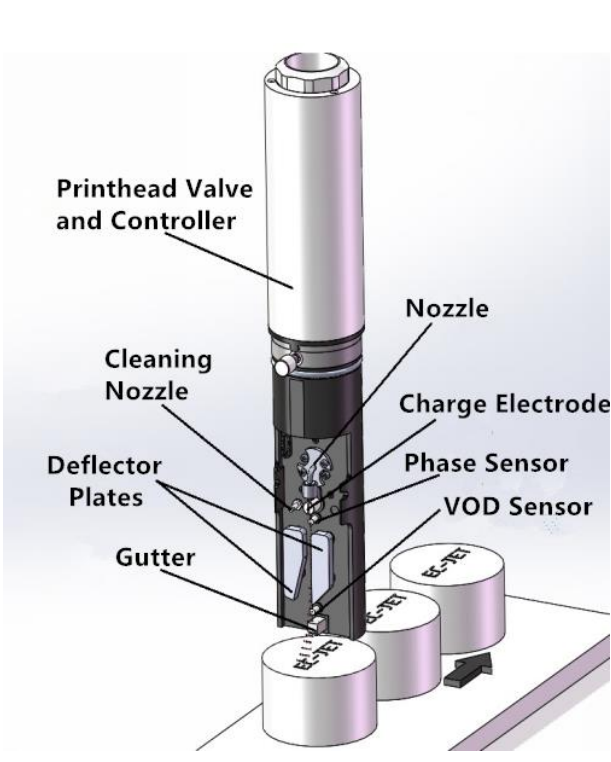

CIJ (small character inkjet printer) technology difficulties:

1. Uncontrollable ink drop electrostatic interference

In the process of jet printing, the charged ink drop in the ink line will not only be displaced by its own electricity and the electric field of the deflection plate, but also the uncontrollable deflection will be generated in the adjacent charged ink droplet. Therefore, to obtain excellent printing quality, extremely sophisticated sensors and excellent circuit control systems are required.

2. Environmental factors

In the work of the inkjet printer, due to the influence of external environment such as temperature and humidity, the physical and chemical properties of the ink change (mainly the viscosity of the ink), which brings great instability to the printing accuracy.

3. Corrosiveness and fast drying property of ink fluid

The ink of the inkjet printer is highly corrosive and quickly solidifies in the air, which is easy to cause pipeline blockage, which brings great challenges to the design of the ink path system and the material properties inside the inkjet machine.

EC-JET's unique advantages:

1. Research and development Pioneer

EC-JET is an enterprise that stresses great importance to research and development, with an annual R&D investment of more than 30%, and has been awarded "high-tech enterprise" for many years.

2. Lean production and 5s management

a. "One machine one card" traceability

Machine production will be traced in the whole process, each machine is affiliated with "ID card", the whole process tracks and records order configuration, test results and various related information, to ensure impeccable production quality.

b. Overall testing process

All the machines have been going through on&off testing for at least 3 days and 3 nights, and then allowable to make shipment after qualification, to ensure customers with the stability of the product under frequent start & stop conditions.

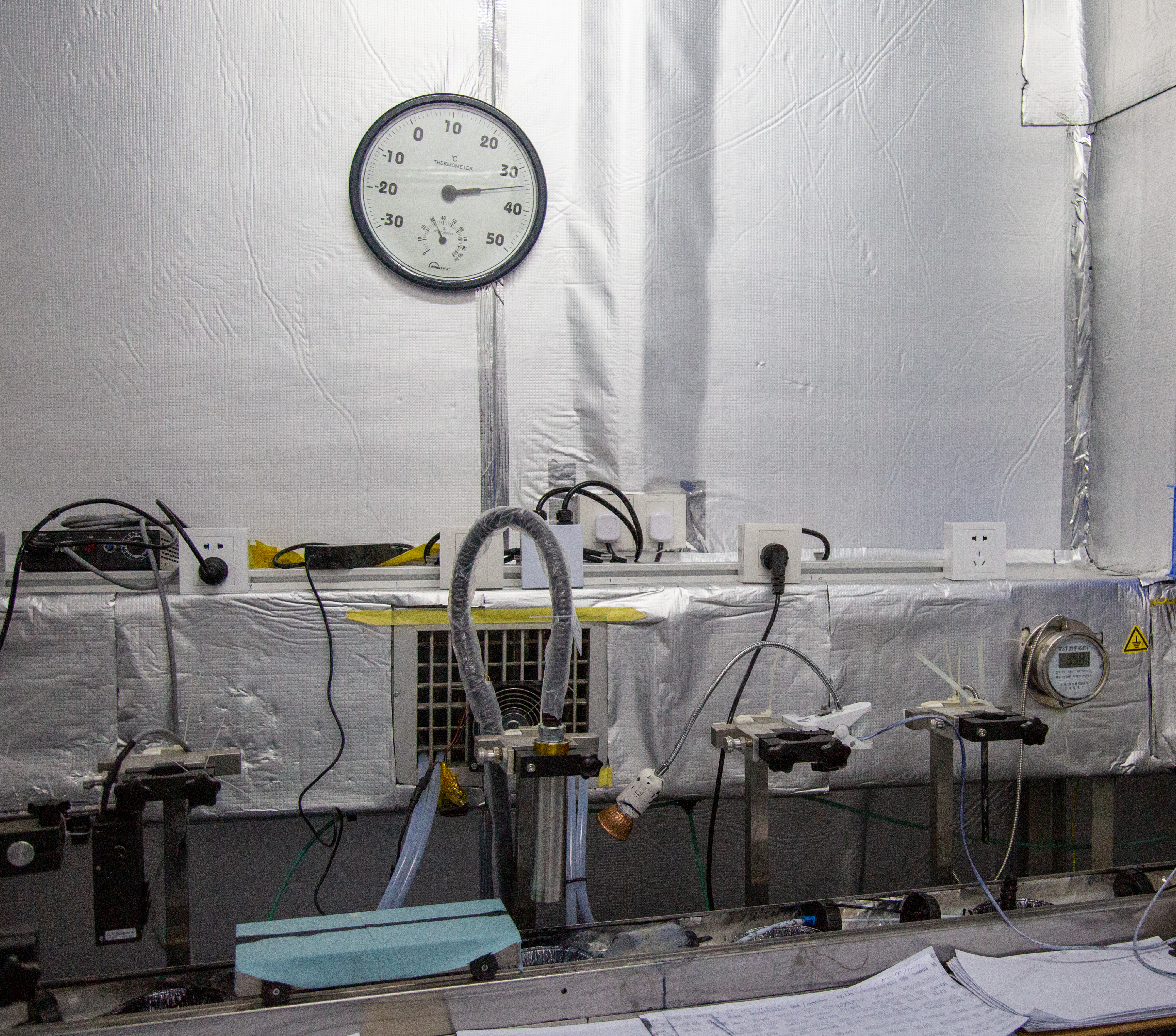

c. Extreme environment test

The machine has been verified by harsh environment and make sure stable operation in the harsh production environment with high temperature and dust.

Choose EC-JET, Achieve excellence!

For nearly 20 years, ET-JET has been committed to exploring and pursuing the limits of CIJ technology, and our uniqueness originates from this persistence. Discover the ultimate precision, reliability, and innovation that EC-JET brings to inkjet and identification fields.

|

|